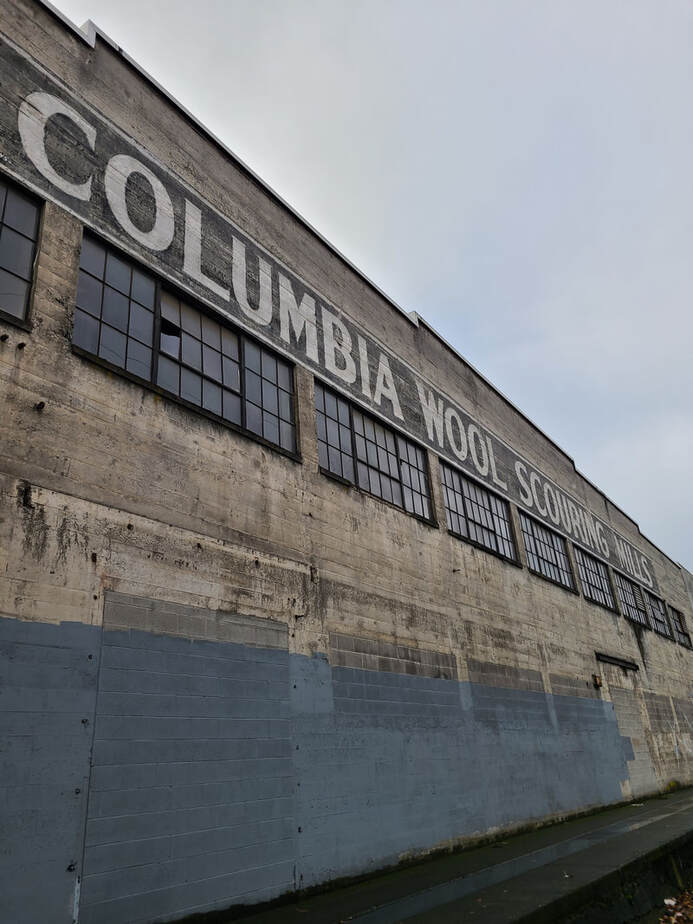

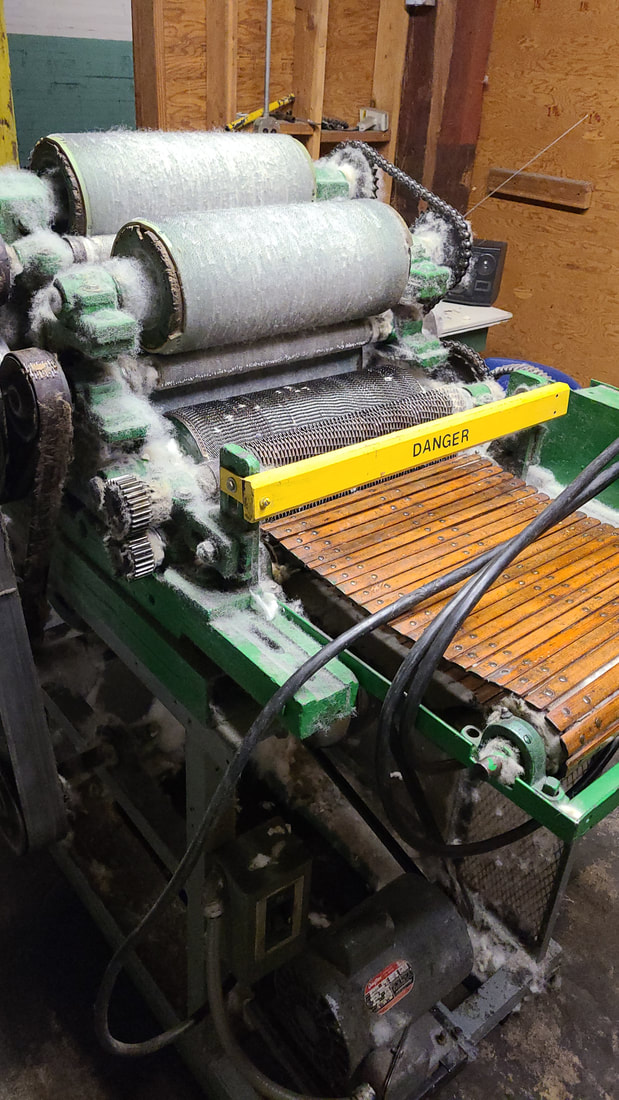

I hope this Thanksgiving week finds you all well and healthy! This holiday season is definitely a bit different from the past isn't it? I'm finding myself, well first surprised that it is already here. In addition feeling a bit less frenetic. I won't be out doing a lot of in person shopping but will instead be hunting down small businesses I can buy from online. Meanwhile Mitch has been busy hanging Christmas lights which will certainly add some holiday spirit to the air. Oh and I'm so glad to see that there are endless cheesy Hallmark-esque movies I can watch on Netflix. My favorite for knitting and spinning! But back to last week. We headed on a quick day trip to Portland so that Mitch could work on some upkeep at our property up there. Meanwhile I made a trip just down the road (literally) to what was once the place that they used to do the wool washing for Pendleton. I love this place. This is my third or fourth visit and everytime I learn more about wool from Keith, Dan and Allen, the guys who run the facility. I have of course gone thru the building before with them, but this time I recorded and have shared some of the videos in Episode 2 of the Being Ewethful video podcast. If you'd like to see, please follow this link and check it out. I thought I would expand on the trip here on the blog... From the moment I drive in I get giddy with excitement. You drive around the back of this big building and there you see a sign painted on the outside "Columbia Wool" with an arrow leading you. The office is just up the stairs and I am always greeted with such a welcome from these guys. And of course, we talk wool! Getting a chance to talk with professionals with such long histories in this industry is an inspiration for me and I always try to take in everything they say. All three of them are able to class wool - classing is a way of sorting wool into different levels of fineness or microns - which is a skill all its own. They all worked here at Pendleton when the scouring mill was operational and have such stories. As we go on our tour I can't help but put all the pieces of equipment back in there place and imagine what it would have been like. The conveyers overhead moving wool to and fro. Employees all around running the machines. And the level of noise as all the machines were doing their jobs. It is such a big impressive building that it brings me joy to think of it fully operational. These days the facility is used for a couple purposes. One is that it is a place where local shepherds and shearers come to sell their raw wool. As Keith mentioned, most of the local wool that is dropped off is not enough quantity to fill one bale. So one of their jobs is to sort thru the wool, class it and re-bale it for cleaning. They are looking for white wool only so any other natural colored wool is immediately pulled. The reason for white wool is that it dyes up easily and uniformly. After being skirted thru, the re-baled wool is shipped to Texas for scouring (washing). This used to be the main job of this facility. Years ago the scouring ceased happening here. The main reason being that water is expensive (I can attest to that given the business I used to own down the street!). Both the amount used and the output. And of course all that is put back out in the water is closely monitored and charged accordingly. The wool soaps, the lanolin, the debris are all taken into account. The long and short of it is that the cost to clean the wool at the facility became more than the cost to ship all the wool by trucks to a scouring facility in Texas. So that is how it is done now. Actually most of the wool scouring in our country is done in Texas. After it is clean the wool is shipped back to the facility in Portland and/or the two mills in Washougal, WA or Pendleton, OR. In addition to overseeing the movement raw wool to and fro, this site in Portland is also where most of the wool from around the world is shipped to. The main countries that they receive their wool from are Australia, New Zealand and South America. The main reasons they are importing wool is that it is hard for them to get enough of the wool they are looking for in the US. They need very low vegetable matter as well as branding paint-free white wool (a paint is often sprayed on the backs of sheep to denote whom the sheep belong too). Apparently the wool out of Australia has only 0.1% vegetable matter. Now that is low! The reason it is so low is that they are mainly out on large pastures with shorter grass which keeps vegetable matter and mud to a minimum. As you walk the building you are surrounded by massive bales of wool. Each bale is stamped with the grade of wool inside and it all will be used for different Pendleton products. The finer end (lower micron count and softer) is generally used for their mens shirts and other next to skin apparel. The courser wools go towards items such as blankets. As for what I bought. I got one beautiful fine wool fleece that I hope to crack into this weekend for a bit more skirting. I'm not sure what I will do with this fleece? Play most likely! I also bought another secret batch of wool which I'll let you in on in a few weeks. So there you have it. A little more about my trip. They do accept visitors but during the pandemic and out of respect I would advise that you call ahead first. Also you must WEAR A MASK!!! As always thank you for reading. And now for watching too! Please be safe this holiday week. Do a lot of making and when you are out and about please wear a mask! Until next week, craft on!

1 Comment

I can't help but express my immense gratitude for your invaluable travel tips and guides. Your posts serve as my trusty companions in planning my journeys. The in-depth insights you provide, along with personal anecdotes, create a unique and engaging reading experience. It's evident that you pour your heart and soul into each article, and it doesn't go unnoticed. Your travel blogs are a testament to your passion for exploration, and I'm thankful for the wisdom you impart to us fellow travelers.

Reply

Leave a Reply. |

AuthorI am Kim Biegler, the owner and operator of Ewethful Fiber Farm & Mill. I create hand spinning fibers from locally sourced wool and teach others online how to hand spin their own yarn. Archives

August 2023

Categories |

RSS Feed

RSS Feed