|

Have you ever been sitting in a knitting group stitching away when you notice someone clipping along and knitting in a very different style than you? This is how I first learned about continental knitting. A woman in a knit group was cruising through her project and she didn't even seem to be moving her hands. Turns out she was knitting continental style! What's the difference? Continental knitting uses your left hand as the one that handles the working yarn. The forefinger holds the yarn very close to the needle and in essence you are picking up the stitch, knitting the stitch and then sliding the new stitch off the needle in one small smooth movement. This as opposed to English knitting, or "throwing" as I will refer to it moving forward, in which you are using your right hand to handle the working yarn and you are "throwing" the yarn over the needle before you even get to work the knit stitch. Here are 5 great reasons to add continental knitting to your skillset: 1. Faster. This is a biggie! Continental knitting is significantly faster than throwing. The reason being that there is less action taking place. Continental is a quick pick up and slide whereas throwing takes a wrapping motion, then the stitch, then the removal of the stitch. Now most of us aren't trying to run a marathon with our knitting but it doesn't hurt to be a little faster - quicker to get to the next cast on! 2. Ergonomics. Being able to use both hands to knit allows you to reduce overuse by switching between hands with different projects. Please note that I say "different" projects. You always want to pick one way and stick with it through a project as your gauge will likely be very different with the different techniques. Tip: Write notes on each pattern to remind yourself which style you were knitting just in case you put it aside and forget. 3. Left handed. Continental knitting uses the left hand as the dominant hand so if you are naturally a left handed person this technique will be much more intuitive than "throwing" your yarn. 4. Colorwork. Being able to knit with both hands is a game changer for knitting stranded colorwork. If you are a thrower you have to keep putting your yarn down and to switch colors. If you are able to knit with both hands you can have a color in each hand and go back and forth without stopping for color changes! 5. More Consistent Tension and gauge. The idea with continental knitting is that there is very little space between your forefinger and the needle which not only makes knitting faster it also leads to a more consistent tension that is created more by the needle than it is by you and the yarn. If the needles are determining tension vs. you the human, you will undoubtedly get more consistent gauge. There you have it! A little of the what and why's to knitting continental. Are you ready to learn?

1 Comment

I recently posted a video on Instagram of me conditioning some clean picked wool prior to starting to card the wool. This post garnered a lot of questions about why I do this and what the conditioner I use is. I thought I would dive in a little deeper here.

First the why? When processing wool static can start to build up between the fibers. This static will cause issues during carding (and spinning) and not allow the fibers to process as well. During the dry summer and winter days this becomes more of an issue. Conditioning the fiber is a way to combat that static. In addition it adds a little moisture back into the wool just like when we condition our own hair. Now the what? At the mill I use a specific type of commercially processed conditioner. Have no fear, prior to owning the mill I did condition my fibers as need and wanted to let you know you can do this as well. I scoured (no pun intended) through all of my wool books and confirmed that the easiest at home recipe for carding oil is a 50/50 ratio of olive oil and water. Mix it up and add to a spray bottle so you have it on hand. Give it a good shake before you start to use it each time and be sure to have the nozzle set to mist. And finally the how? My best advice is to play with the conditioning oil as needed. If it is a dry season you may want to automatically condition the wool prior to starting to card or comb it. You can do this by having your squirt bottle on the mist setting and lightly misting the wool. I generally fluff the wool a bit after spraying to disperse the oil. Then let is sit for an hour or so to absorb. The wool will absorb the oil! Then resume processing. You can also lightly mist as you go along. The only issue with that is that the wool may feel a little damp. My best advice is make the mix up and do some experimenting to see what will work well in your climate! Chain plying is a way of using the hand spun yarn on a single bobbin to create a finished 3-ply yarn. You are plying this singles yarn on itself similar to how you make a crochet chain. It is a fun and efficient way to ply!

So why chain ply you may ask? Here are my top reasons for using this technique of plying.

Saturday nights are my nights for relaxation in my craft room. After dinner I head upstairs, turn on the Hallmark channel (I know I know) and settle in with my favorite cocktail surrounded by all my crafts. On a recent Saturday I wove for a bit and then decided it was time to spin, but I did something I never do, and picked up my drop spindle. There was literally yarn I had spun on it from 2 years ago - the only yarn I had spun on it I should add. So I spun more! Then pulled that yarn off and spun more. It was so relaxing, rhythmic and I felt so connected to the fiber as I continually wound the freshly spun yarn onto the spindle. Does this sound joyful to you? If you need just a bit more temptation here are my top 5 reasons you should pick up a drop spindle.

1. You'll be making yarn! And making yarn is the best. Whether you are a knitter, crocheter, weaver or have no other yarn hobby, you can make yarn! 2. Budget friendly. It doesn't cost much to get into this craft. You can easily find a drop spindle for around $15 and with a $20 purchase in wool roving you are ready to go! Of course you can spend more on both spindles and fibers but the initial cost to get in the game and make lovely yarns is low. 3. Portability. Drop spindles are small and can easily go anywhere with you. The can go straight into your project bag, purse or easily fit in your suitcase so you can make yarn on the go. 4. Relaxing. Handspinning is easily the most relaxing craft I do. There is something about the flow of it, the feel of the fiber running through your hands and the slow rhythm that accompanies spinning. It is a surefire way to lower your heart rate and your stress level. 5. Variety. There are so many varieties of drop spindles! Top whorl, bottom whorl, Turkish. Light or heavy. Handmade gems, 3D printed or a vintage find you can never get bored experimenting. Plus a collection makes for a great display! I hope this inspires a few of you to pick up that drop spindle that has been sitting on the shelf or maybe do some searching on Etsy for a drop spindle to get you going. Have fun and make yarn! Here is a link to a great little Etsy shop I have bought beginner drop spindles from before... https://www.etsy.com/shop/theknitstore?ref=simple-shop-header-name&listing_id=90346042 If you have ever tried to dye yarn red you may know that it is not as easy as it looks. It is pretty easy to get a pink yarn, but getting a luscious deep red is not as easy. For my yarn club I did a lot of red dyeing over the 2021 holiday season and I wanted to share my top tips for getting the red yarn of your dreams. Please note for this red yarn I was dyeing wool/alpaca blend yarn using Dharma's Oxblood Red acid dye. I soaked the yarns in water with a drop of Dawn dish soap for at least 30 minutes prior to dyeing.

1. Saturate. Use a lot of dye. If you are generally conservative with your dyes scrap that and go heavy with the red. This is definitely where you can read the manufacturers labels and go there to get that full color. You can always pull back in the future. 2. Use a good amount of mordant. Whether you use citric acid or vinegar use a bit more than usual to help the yarn take up as much dye as it can. 3. Heat. And cooling for that matter! Definitely bring your yarn slowly up to a good high temperature while it is sitting in the dye. I like to get to about 180 degrees. The best uptake happens at that high temperature. Equally important with red is letting it come back to room temperature naturally. I leave the lid on my red dye pots to allow for a slow cool down that generally pulls up any last remaining color in the pot. It is all about trial and error with dyes and yarn, but hopefully these tips can help you skip a couple of the errors and get straight to the color you want! Have fun! Last month the mill shop open day brought me such joy. The shop was full of not only shoppers but lots of makers from all different towns who came to sit, chat, make and share. I remember looking up and seeing several women standing around another who was showing off the blanket she was making. Everyone was so supportive and excited of her endeavor it truly hit home how important our fiber community is to so many of us.

I realize it is a bit crazy in the world and not everyone is comfortable being out in public but luckily there other options to in person meet-ups. Being part of a vlogging community or even joining a local guild or yarn shop via zoom can help give you energy and social contact. In my most recent Being Ewethful vlog episode I asked viewers why fiber community is important to them and I thought I would share everyone's thoughts in hopes that it motivates you to find a community that supports and connects. Benefits of Being a Part of a Fiber Commuity... 1. Gaining inspiration from what others are doing and being able to inspire others with your projects. 2. Introvert friendly One of the great things about making in a group is that if you don't feel comfortable speaking no one cares! Everyone is so busy working on their projects and just enjoying each other that there is no awkward silences or silence... because you just work right thru them! 3. Sharing knowledge and learning from each other is one of my favorite things about social making. I always garner some new piece of information that makes my projects easier down the road. 4. Vlogs and blogs are always there. Whenever you are feeling a little lonely or are needing a little inspiration you can always go online. Finding a fiber friend is as easy as clicking play on a vlog on YouTube. Even in the middle of the night, no matter your craft, you can always find someone talking about and sharing what they are working on. 5. Seeing what others are making. Whether online or in person it is always fun to see what projects other makers are working on. You can get an idea for future projects, see different materials, yarns and wools in action and sometimes even decide you are absolutely not going to do that! Let's face it, even though we want to do it all, there just isn't enough time in the day. 6. Staying connected. This seems especially important during these pandemic times. Staying connected helps keep our moods up and our brains working. This is also true for those of us living out of town and/or those working from home with less social interaction. Plus as socializing is an important aspect of keeping our brains healthy as we age. 7. Getting help. Stuck on a project or don't know how to fix a mistake? There is always someone in a group that has an idea of how to move forward. Of course be mindful not to take up too much of someone's time, but helping each other out is part of being in a community. So there you go! I hope this has given you some room for thought and inspires you to throw on your mask and venture out to a local meet-up. Or maybe click onto zoom or YouTube to find your online place. This is a such a wonderful community and you will be welcomed with open arms and ideas!!! my

Variegated yarns are yarns that are dyed different colors in the same skein of yarn. They are so fun to work with as the color is constantly changing throughout the skein! I am pretty sure I was watching a video by Essence of Autumn dyeing in this way and thought it would be fun to try. The idea of this technique is that the dye is not able to penetrate the yarn evenly due to the twist. It was indeed fun and made such unique yarn that now once a year after spring shearing I buy all the wool from a local Jacob sheep farm, process the wool out into a worsted weight very rustic yarn, and then dye about half of the yarn using this technique with acid dyes for wool. Since I am working with 100% wool yarn that has been untreated the pre-soak, citric acid mordant, and heat play an extra important role in getting the dye to take. I have found the heat to be an extremely important part of exhuasting the dye with natural yarns so I like to make sure I get to as high a temperature as I can but not simmering ~ 180 degrees. 1. Soak yarn in a water bath with a drop of Dawn dish detergent mixed in for at least 30 minutes prior to dyeing. 2. Add water to your dye pan. Using a casserole pan or larger (I use a metal commercial size pan) fill until the water will cover most of the yarn once it is twisted. 3. Add citric acid to the water and mix in well. Citric acid is the mordant that will help the dye adhere to your yarn. (I add about 1 TBSN of citric acid for 2-3 skeins) For this type of dyeing you want the citric acid already in the water to ensure the yarn picks up the dye quickly which helps to cause a secondary uneven tonal effect. 4. Twist your skeins individually and lay lenghtwise in your pan. I twist the skeins by simply holding the top of one and twisting slowly moving downward along until the whole skein until I reach the bottom of the skein. I recommend adding extra twist as the yarn will settle a bit once it gets into the water. 5. Turn the heat on and let water heat up. Once some steam starts to rise I add the first color to the pan pouring it in stripes from one end of the pan the other. It really doesn't have to be perfect because the yarn is going to pick it up in different ways so don't stress too much. I then use my plastic mixing spoon to push down the yarn and move the yarn around a bit. If twisted parts of the yarn are sticking out of the water just use your plastic spoon to gently push the bumps down for long enough to let them pick up some dye in those parts. 6. Allow the water to heat until just under simmering and the dye has exhausted out meaning the water is just about clear. 7. Open up the skeins. Once the water is just about clear, turn the heat down a bit and open up the skeins so all the yarn is exposed in the water. BE CAREFUL as the water AND yarn are very hot. I use tongs to pull the yarn out and let it naturally unwind. While holding with tongs I use the plastic spoon to help place the opened yarn back in the water. 8. Add the second color. Again it doesn't have to be exact as the yarn is going to pick up the color irregularly. I use the same method pouring in stripes from one end to another and then using my platics spoon to push the yarn down and move the dye around a bit. 9. Bring heat back again until water is just under simmer and let it be! 10. Let it cool. Once the water has exhausted again turn off the heat and let everything cool to room temperature in the pan. I most often just leave my yarn to sit overnight to ensure it is cool and that the dye is set. That is all there is to making this fun variegated yarn! There are so many different dye techniques and lots of wonderful dyers out there sharing what they know. Some of my favorites are Essence of Autumn (as mentioned above), Fiber for the People and Hue Loco. Craftsy also offers a whole series of acid dyeing videos if you want to invest a little bit of money in their subscription service. I hope this helps you experiment with a new dyeing technique! Please feel free to ask any questions below or tell me about your favorite technique. Thank you for reading! I recently dove down a rabbit hole of handspinning wheels when I was sitting at my Ashford Kiwi wheel thinking to myself, why does the yarn on my bobbin look all wrong? Now keep in mind that this was my first spinning wheel, the wheel I spun on for years, but as of recently I mainly use it as the wheel I ply yarn on. Well there was a reason the yarn looked different. Not because it was wrong but as I found out thru research simply because of the type of wheel it is. I could not believe how much I didn't know about my wheels and want to share a little of what I learned with you here. Let's start with the basics, there are 3 main types of spinning wheel when it comes to mechanics.  Pictured is an Ashford Traditional spinning wheel. You can see there is one band from the drive wheel to the flyer whorl. The Scotch Tension is the metal coil and wire to the right. Pictured is an Ashford Traditional spinning wheel. You can see there is one band from the drive wheel to the flyer whorl. The Scotch Tension is the metal coil and wire to the right. 1. Single Drive, Flyer lead or Scotch Tension wheels This is the most commonly used type of wheel. The Scotch tension wheel, as it is often called, allows for the most adjustments making it able to spin a lot of different yarn weights.

Pictured is a Kromski Minstrel spinning wheel. You can see the band loops from the drive wheel over the bobbin and the whorl of the flyer. Pictured is a Kromski Minstrel spinning wheel. You can see the band loops from the drive wheel over the bobbin and the whorl of the flyer. 2. Double Drive wheels This type of wheel has the ability to spin the finest yarns. This is also the most complex of the wheel types.

Pictured is a Louet S75 spinning wheel. You can see the band attaches from the drive wheel to the bobbin. In the lower portion of the photo you can see the band over the flyer shaft to adjusting tension. Pictured is a Louet S75 spinning wheel. You can see the band attaches from the drive wheel to the bobbin. In the lower portion of the photo you can see the band over the flyer shaft to adjusting tension. 3. Single Drive, Bobbin lead wheels This type of wheel is very simple but also the most difficult to make adjustments to.

I have garnered a lot of my information from a very comprehensive book called The Big Book of Handspinning by Alden Amos. This book is densely filled with all the information you may ever need to know about the craft.

So there you have it. A brief introduction into different spinning wheel mechanics! Please keep in mind that these 3 types come in all different shapes, sizes and styles. If you aren't sure what kind of wheel you have, sit down and take a look at how many band loops you have and where they are c onnected? This should help you answer the question. I also walk step by step thru the wheels in Episode 22 of Being Ewethful on YouTube. I will be going more in depth with each wheel over the coming months so please stay tuned for more videos that I hope will help you on your handspinning journey. What kind of wheel(s) do you have? What is your favorite and/or what wheel do you long to own one day? I would love to hear from you! Have you been thinking about buying a raw fleece for processing into yarn but been nervous about what to look for? I just came back from a big wool buy in Eastern Oregon and it got me to thinking about what tips I could share with you about how I pick my fleeces. So here are some of my top tips to help you feel more confident about finding quality wool.

Before you head out to the farm or festival to buy that fleece, there are a couple things to consider. .. First off is the offer of "free" wool. I always take pause when I am offered free wool. Generally free wool is offered by people that have the animals for reasons other than the fiber and therefore they aren't raising the animals with the wool in mind. Often times this wool has issues such as loads of vegetable matter, excess mud, was not shorn with care or even just hasn't been stored well. Obviously this is not always the case, but worth taking note. Conversely, just because it is for sale does not make it great wool. So dig in and make sure you are getting what you want. Another thing to consider before buying a fleece is how are you going to process it? Are you going to do it yourself with handcards, combs, or your own carding machine? Or are you planning to send it to a mill for processing? Different breeds fleeces tend to do better with different processing types and even different mills. Make sure you know how you are going to turn this wool into yarn before you buy so that you can narrow your search a bit and that once purchased, the fleece doesn't just sit untouched in a corner. Now that you have that all figured out, its time to shop! Here are my top tips to purchasing a quality fleece. 1. Check for wool moths. When you open the bag to look at the fleece make sure there are no wool moths or larvae visible. The larva of wool moths eat at the fiber effectively damaging it so I would recommend passing on wool with signs of moths. It is also polite to mention the moths to the seller so they can dispose of the fleece. Here is a quick reference link on wool moths but you can find an abundance of information with a quick google search. And please take note that all moths are not the same and most do not eat wool so it is good to know what you are looking for. 2. Gently open the fleece up and dig in a little bit. Be courteous and don't rip the fiber apart. But it should be ok to take a sneak peek inside the fleece and maybe pull a couple locks from different areas. Fleeces generally are rolled with the cut end showing. The cut end generally looks very clean so it is important to get a good look inside the fleece to determine if you like the fiber. 3. Check the amount of vegetable matter. Coated fleeces should have minimal VM (vegetable matter). Pasture raised animals also tend to have minimal VM. Prices often vary dependent on this so if you are patient with picking, you may be able to get a good deal on a fleece with a little more vegetable matter. This is totally up to you the buyer to decide what is acceptable. I generally don't mind moderate vegetable matter, but if the whole barn floor is in the fleece, I pass! If you are going to send the fleece to a mill, you should definitely pick out the VM prior to drop off. 4. Do the snap test. Take a lock of the wool out and holding your fingers at each end of the lock, hold the lock up by your ear and do a quick motion with the lock to stretch it. A strong fleece should make a clear pop sound. A weaker fleece may sound a little crackled or even break on the snap test. A solid pop is want you for ease of processing. 5. Test the tips. Again look at that lock this time looking at the tips. If they look a little frizzled, you can take the tips between your fingers and give a little tug. A strong fleece will stay together, a fleece with weak tips may break off. You may still be able to gently hand process this fleece at home, but if you are looking to have it milled be aware the tips may break off during processing. Well there you have it, some of the top things I look at when I'm on a wool buy! When in doubt a good fiber farmer will always be able to offer advice and even point you in the right direction so it never hurts to as for help! I hope this helps a bit with your next fleece purchase. Please feel free to comment below and/or ask any questions. I am always glad to help! And then the rain came...

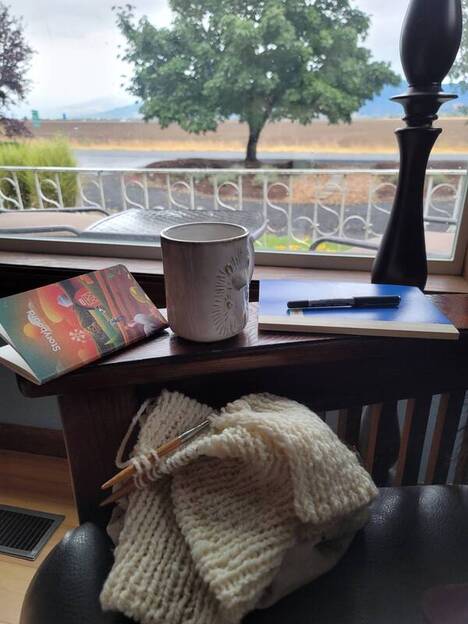

A storm came in last night bringing the first rain we have had in months. I heard it all thru the night, a sound that seems so unfamiliar now but oh so welcome! I usually get up before Mitch, the dogs and I wander out for morning potties and down to the barns to let the animals out for the day. Then its back to the house to prepare breakfast and lunches for the day, do laundry, and carry on with daily chores and work. But today I came back into the house, made coffee, grabbed my knitting and sat. I sat in the big leather chair with the lambskin thrown over it by our big front window. The very chair that has been beckoning me all summer to come sit for a bit. It was gloriously quiet and so luxurious. Before moving to the agricultural world rain didn't play the same role in my life as it plays now. There was a time before when it seemed more like drudgery. That was before it had such an effect our livelihood. Before I understood it is what feeds our crops and animals and in turn us. Before I truly understood that our climate is changing. I'll admit there was a time when I took our beloved PNW rain for granted. Now as I sit I appreciate what the first rain does, it brings with it an exhale. I could see it this morning in the grass seed fields and in the pastures which went from loose dirt to damp dark soil. I could see it in the animals as they ran to me for morning kibble, not having to breath in the dry and particulates they normally have been kicking up along the way. I could see it in a farmer I know who slept a wink longer than normal having heard the rain come in overnight. And for us makers, for me as a maker, the rain brings a chance to sit. A chance to breathe deep, a chance to wrap myself in wool, a chance to be inspired by nature's reinvigoration and a chance to let that inspiration flow as I think about what my hands will make and write this coming winter. Gratitude times a million for these moments! Wherever you are I would love to hear what the first rain of the season means to you? Do you have a favorite spot to watch the rain from? Have you been able to sit and have that moment of inspiration yet? |

AuthorI am Kim Biegler, the owner and operator of Ewethful Fiber Farm & Mill. I create hand spinning fibers from locally sourced wool and teach others online how to hand spin their own yarn. Archives

August 2023

Categories |

RSS Feed

RSS Feed