|

Hi everyone! It's been a hot minute since I've been here but here I am! In the midst of running in all the directions for the business and farm (while being sure to take a little down time) I kept thinking, I really need to sit down and blog. So finally! This morning I went and picked up the new chickens to the farm. They are all settled in for the day so it seemed a perfect time to sit myself down and write. I got back from a road trip to California last week (I'm fully vaccinated!) which involved a lot of time alone in the car. I listened to endless business podcasts from how to market, manage your money or just stories of other entrepreneurs. I love this stuff, weird as it is. I love hearing about how others came up with their ideas and the different ways we all go thru the same struggles to make it work. This is especially fascinating to me as I work on transitioning the business along with the pivots that have come with the last year. I've talked a bit on the Being Ewethful vlog on YouTube about starting to move the mill in a different direction. My long term goal when I purchased the equipment and started the Mill was to eventually have our own line of Ewethful yarns and fibers for handspinners. We are now getting to the point in the business where financially I can start to take a little step back from processing for others and work more on our own product. The reality is that when I process for others, they pay me as soon as the job is done. Conversely, with our own product, not only do I go thru the work of making the product but I then also have to sell that product to make any money. If nothing sells, no money is made. So there is a little leap of faith and a lot of work going into this transition! Ok ok so with all this transition and change and 4 years into Ewethful, it seemed the right time to come up with a new mission statement. I've been working on this for the past couple months but just wasn't quite getting what I wanted. Then right before the road trip I listened to a podcast that had a guest who was talking about mission statements. There was about a minute of the interview where the woman said a couple things that hit me. I actually listened to it several times and even wrote notes on what she said. I took all of this, scratched most of my previous drafts and let my brain clear and think on the road. Then I started reading the book Primal Branding by Patrick Hanlon and within 10 pages I read another companies mission statement and it just clicked in my brain. So I sat down in my Mom's dining room by the beach and wrote it up. She read thru it a couple times with me. We sent it off to Mitch and he texted back "Perfect." Finally! So what is our new mission statement? Hopefully its a bit bold, a bit inspiring and it tells a bit of where the business is headed.... Our mission at Ewethful Fiber Mill is to fill making hands with small batch American grown yarns and fibers. We strive to produce lightly processed products that maintain their character, have low environmental impact and tell the stories of the animals and shepherds from whence they came. So there it is! I'd love to hear your thoughts so please comment below. Thank you as always for reading and supporting Ewethful. I hope you all have the privilege of being fully vaccinated (or are close) and get to hug the ones you love so very soon! Please note I will be vending live and in person in Scio, Oregon at the Fat Lamb Fiber Festival. It is May 22nd, 10am - 6pm. A small event but full of fibers, yarns and excitement. Follow the link for more details. Click here for details.

9 Comments

Drilla and her lamb Patrick. Don't worry, its just Pepto Bismol on his lips! Drilla and her lamb Patrick. Don't worry, its just Pepto Bismol on his lips! What else would I write about but lambs this week! And what a week it has been! I have the greatest appreciation for the work that goes into lambing on a larger scale. For us it is a smaller endeavor as we only bred four of our ewes back in November. The way this works is that you put your ram in with the girls for about a month and let them do their work. The reason you leave them together for a month is hopefully to catch the girls cycling twice during the month, allowing for a better chance of conception. Then you wait. Gestation for a pregnant ewe is about 145 days - give or take a few days either way. So you do the math. We do not track when our ewes are mounted so we generally go 145 day from the first day they were with the rams and count forward since we don't know exactly when they "did the deed." From that date forward you know you have about a month window in which you should lamb if they are pregnant. Our girl Taraji lambed first about two weeks into that month lambing period. She has lambed for us before and it was almost the exact same situation. No signs of anyone in labor so I went off to work. I had some idea she had lambed when I pulled into the property because the other girls were all out to pasture and she was alone tucked away in the shed. I walked down the hill and sure enough a lamb head popped up next to her. There is nothing cuter than that! Once the lamb is on the ground you want to put mama and baby into their own private space or "Jug" so they can have alone bonding time. It also allows you to closely monitor if baby is nursing well and if mom is recovering well and doing her duties. Mitch built the jugs into a barn stall a couple months ago so we were all set. To get them in there you pick up the baby, hold it low to the ground so mama can see where it is, and start walking showing her her lamb the whole time. Good moms get pretty fired up and follow. Occasionally they lose sight of them so you put the baby back on the ground, wait for mom to catch up, and onward. Once in the jug mom can relax a bit knowing her and her baby are in a safe space. Little Johnny Rose as we called Taraji's baby, was born on March 24th and it was a whole week before the next girl went into labor. Drilla is the first ewe we purchased and has never lambed before. She was a whole different story. She isolated herself the evening before she actually went into true labor so we started watching her as soon as this happened. It wasn't until the afternoon of the following day that she really started into big contractions and real pushing. It went on way too long and after too long of having seen hooves first appear I realized I may have to pull the baby. Trust me, I begged and pleaded with whomever to please let her deliver on her own. No joke, I was terrified. I called Mitch and told him what was going on so he headed home. Just after that I finally saw a nose. Good sign. But she was obviously struggling to get the head out any further after many large contractions. Once I realized the amniotic sac was broken I thought "oh s*** I've got to do this." Truth is I thought at this point the baby was dead. I wasn't sure when the sac broke but with out it and with the baby's nose occasionally popping back inside mom between contractions, I knew I had to end this for Drilla either way. So I put on some gloves, tackled her and reached for those tiny hooves. I blew on little ones nose and saw the tongue move. This was all I needed to truly know it was time to come out. Once I had Drilla she gave in and as I started to pull I could feel her body relax a little. She was so tired and it was obvious immediately that she was happy for the help. Luckily I had gone to lambing school at Iron Water Ranch back in the early part of the year so felt as prepared as I could. I pulled the lamb out past the shoulders and then let Drilla finish. An all black lamb fell out and was alive!!! He immediately started wiggling and trying to get up. Yes!!! I put my sister Heather on a video call and she got to watch the end. My mom watched it later and was just amazed by how quickly he started trying to get up. Just about as soon as they hit the ground, a healthy lamb will be trying to stand and walk to find mom and nurse. For these guys in nature, if you can't get up and walk, you aren't going to make it. So that is the Drilla story! Then came the others quick after that. The following day I noticed labor signs in Sweet Pea or Big Mama as we call her when she is pregnant. This was her third time lambing so we felt confident in her. Watch and wait. Her daughter Cream Puff was also pregnant but for her it was the first time. We pulled them up to the top of the pasture that night and started the regular barn checks. Mitch called me about 1am and said "we have babies!" The true shock when I ran down was that it wasn't Big Mama, but her daughter Cream Puff who had delivered. And even more shocking than her having twins (2 boys) was that one baby was black with a white head and the other one black and white. Both of these ewes are white and both our rams are pretty light so I didn't think I had a chance of dark sheep. Wahoo!!!! I was so proud of her for being such a good mama from the start! Into a jug they went and since Big Mama was obviously in labor we pulled her into the barn. Hourly barn checks continued. Around 6am I walked in and there were two fresh lambs with an attentive mom licking away. A white girl and a black girl with a fluffy white head. Where the heck did all these black sheep come from?! Genetics are a crazy thing! So here we are, two days from the last lambs being born. Patrick, the little black sheep with the rough delivery has been having some diarrhea and was a little less energetic so I have been giving him a lot of extra supportive care. Diarrhea can turn quickly if they get dehydrated. This morning at barn check he was the first lamb to pop up, stretch and nurse. Yay!!! And all the other lambs and moms looked good and healthy so I refreshed waters and food and left the barn with my first sense of relief in weeks. Hopefully from here on out our job will mostly be to watch, clean and enjoy the spring lamb cuteness. We still need to vaccinate and I will slowly be banding the boys (castrating) over the next couple days but the rest their moms can take care of. We will not be lambing for several years now so we will be keeping all these babies. Plus how could I not with the lovely fleeces to come!!! Yay for my mamas for being rockstars! I'll be posting a Ewethful Minisode tomorrow on YouTube with endless lambs so if you need to just sit and watch lambs, watch for it on Saturday! Thank you for visiting the blog and supporting Ewethful!!! Enjoy the photos and take care everyone. Who doesn't love a good giveaway?! If you are here you likely watched Episode 8 of the Being Ewethful vlog. Thank you so much for watching and for coming to check out the blog site.

There will be one winner who gets to pick either 4oz of handspinning fiber from our March fiber club or a skein of our latest Yarn Club yarn. If you watched the podcast, you'll know what the fiber and yarns look like. I didn't post pics quite yet as I don't want to spoil the surprise for any club members that haven't seen them yet. A special gift will be included as well! To enter to win all you have to do is comment below. To make it easier I would love your feedback. I have been toying with the idea of breaking the podcast up into shorter segments that I would publish maybe twice a week instead of all in one long episode. I would likely float between the main topics: the farm, the mill, fiber and yarn. As the weather starts to shift and the world starts to open up a bit, I wonder if shorter episodes might be easier for you viewers? Or maybe you love the big long one once every two weeks? Any input would be appreciated. Or just comment hi to enter. No pressure. Only one entry per person. Winner will be chosen at random. Entries will be closed end of day (in Oregon) on Wednesday March 17th. Please note I will comment here on the blog to the winner. If you would like to be kept in the loop you may want to mark that you would like to be notified if a response is made to your comment - simply check the box when you comment. Or check back in on Thursday the 18th to see if you have won. Thank you all so much for watching, reading, buying and supporting in any way you do. A couple weeks ago I innocently walked into Eugene Textile Center to grab a couple of new dye colors since I was in the neighborhood. I started talking to one of the employees and asked about this little weaving loom that was sitting on the table. We talked about it for a brief moment and I stared at it thinking, well that's just regular wool yarn that is on the loom and it is pretty small so doesn't take up a lot of room. Then I left. Later that night I looked up rigid heddle looms, as I had learned that style of loom was called. They were affordable for that smaller size, right around $200 - which after being a handspinner seemed like a deal! I mentioned the loom to Mitch then asked my Mom a few questions about weaving as she is a weaver herself. Cool, now I know. It took about 2 weeks before I finally broke. I just couldn't get that loom out of my head. I ran thru all the pros; It would afford me a chance to use up so much of the excess yarns I have, it is fairly quick to work up scarves and other small items I could then sell as finished products, and it was a great way to showcase Ewethful yarns. Cons? Well of course there were none! So back to ETC I went. I asked about that little loom and they grabbed it, took me to a side table and showed me the basics of weaving... and told me to hang out and play! They know what they are doing, wink wink. Actually they were amazing and so helpful. They took the time to answer my questions and when I hemmed and hawed about which one to order, they steered me in the right direction for me. I ordered a 16" Ashford SampleIt loom. A couple days later the loom arrived, we put it together at home which was an easy task, and then it was time to "warp" the loom. I had been nervous about this part of the process, but between the instruction booklet that came with the loom and the youtube videos put out by Ashford it too was a piece of cake. Next I wound my working yarn onto the shuttle and off I went! Now of course there is a lot to learn. As with knitting and crocheting, you can keep weaving simple or you can go in deep making all sorts of different patterns, textiles and finished items. The possibilities are truly endless and it is so exciting to think all the potential. How deep will I go into weaving? Time will tell. I do love that you can work up finished items fairly quickly which means I can go thru a lot of yarn! I also love how the colors work up so differently with each other vs. in knitting, and I love the new to me flat fabric weaving works up. I have heard countless times from knitters or crocheters that they are intrigued by learning a new craft but are worried it will take time away from their current craft. The truth is that yes it will if you love it. But if you love it wouldn't you rather know! That is how I feel about learning to weave. Yes it does take time away from my knitting and spinning, but that's ok! These are all hobbies and the point is to relax and enjoy the process in what time you want to give. Knowing multiple crafts also allows you to take breaks which are good for your mind and body as well. So what's my point? If you are feeling that itch to learn a new craft... go for it! What's the worst that happens, you love it!!! Take care everyone and stay healthy out here.  I spent yesterday watching the Inauguration, crying happy tears, and dyeing up some yarn. Why not? Inspiration was there and you have to grab it where you can! A couple days ago I posted some pictures of a newly dyed multi-colored Prineville base yarn and an Instagram friend asked what technique I had used. The blog seemed a great place to show the technique as I dyed up some of our freshly spun Shetland yarn yesterday. I learned this technique from watching a video with Sarah Eyre. It is so interesting watching, listening and learning from to other dyers. I am using natural yarn (untreated with the superwash process) which adds an extra challenge to dyeing as it doesn't take up the dye as immediately or saturate as easily as treated wools do. I have noticed that with our well water, heat is a crucial factor in dyeing up my wools. The best saturation seems to take place at higher temperature points. So for this technique I placed the yarn in a citric acid/water mixture and brought the temperature up right away, then lowered it a bit for the dyeing process. A high level of citric acid in the water allows the yarn to take up the dye quickly which is necessary for this technique. Time for dye! I like to start with the color I really want to make sure stays in tact which for this yarn was the blue. I sporadically placed it about the 2 skeins of yarn and let it soak in for a minute.

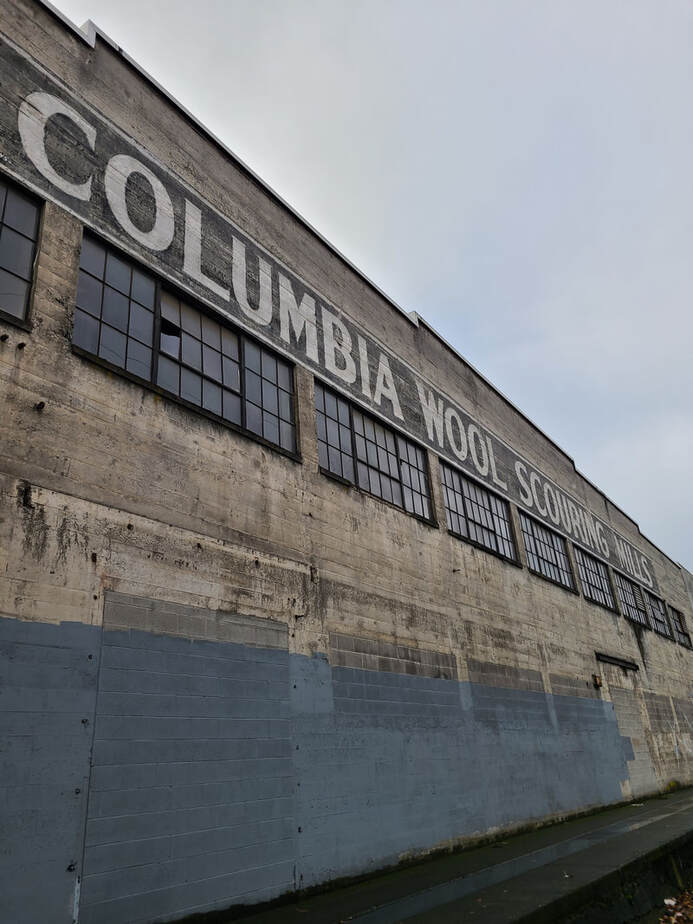

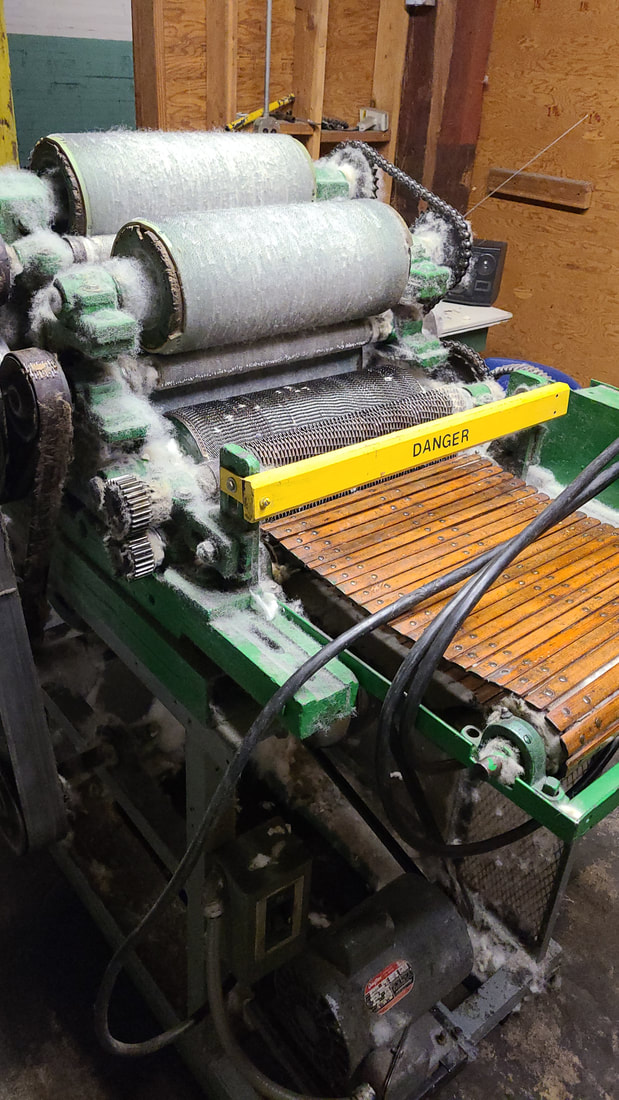

I brought the heat back up and once it appeared most of the dye exhausted (meaning the yarn has pick up the dye so the water is clear) I individually pulled the skeins out of the water for a moment to examine and see if there were spots I'd like to fix. Once I'm happy I let the yarn heat for a few more minutes before turning off the heat. Last step is to let the water cool completely before pulling the yarn out. Generally I leave it overnight. So there you have it! These lovelies will be up in our shop on Friday! The multi-colored is called "Almost Eve" on our Shetland base yarn. The solid blue pictured up top is also on the Shetland base and is called "Moment of Silence." Thank you as always for reading and supporting Ewethful!!! Please stay safe, wear a mask and take care of your fellow humans! Back in the days when the shop and Mill space were open to shopping, classes and fiber group meet-ups, I had a list of "Rules." Don't panic, they were rules meant to help maintain a positive vibe and space for creativity.

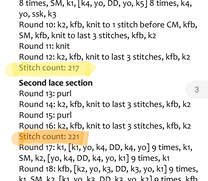

The very first was "Please leave your politics outside our front door." The reason I made this rule was to maintain an open creative space that could serve as a break from what was going on outside. My goal was to welcome all people to the mill, regardless of political affiliations and beliefs, and to allow them to feel safe from being singled out or made to feel as if they didn't belong. For the most part this has worked although over the last 4 years I'll admit that if we all were on the same page politically, the conversations happened and they were fierce and sometimes tinged with a bit of fear. If you've been following me on social media you likely have noticed by now that I have voiced my opinion on multiple issues over the last year. Why the shift? Why put my business at risk of losing clients? Especially in an industry that leans toward the conservative side? Well here's the thing, to me civil and human rights are not fundamentally political, they are the most basic of rights. It seems so simple but obviously not to all. I believe that since I am using social media as a free platform to grow my business, I should also use it as a platform to voice equality and inclusivity for all. My business is a part of me and therefore my core values are a part of it. I have stopped supporting businesses that are touting what to me amounts to racism and/or support of a President who has given racism, hate, and now insurrection a loud voice in our country again. Ewethful has been and will continue to be about creativity, support, acceptance and respect. All of that said, racism and hate will never be tolerated within my business walls or on my social media pages. These core values will be added to the new "Rules" in the Mill. Speak up. Step up. Vote and appreciate that our democracy is indeed fragile. Choose love not hate. If you are still with my business, thank you!!! I appreciate you all so much!!! Stay safe, for the love of all wear a mask because science is real and please take care of your fellow humans.  Pattern clip is from Hint of Autumn by Laura Aylor Pattern clip is from Hint of Autumn by Laura Aylor Can you believe next week is Christmas? And you know what I should be doing? Christmas knitting! But guess what, I'm not. Hahaha! Although after frogging (the nice way to say ripping) back two times on the same spot of my knitting, I was pretty ready to put it in time out. But reality, I was the one who needed a time out. It got me to thinking, why do we make these mistakes while we are knitting or making in general? I mean we are generally following a pattern right? The easiest thing to do would be to blame the pattern? I mean there must be an update to the pattern about a mistake I didn't see right? In this case (and in most cases) that didn't work. There is lace work in this pattern for about 6 rows and then you go back to regular knit and purl with an increase here and there. You would think I would mess up on the lace? Nope. The pattern is well written and has charts that are quite accurate. So I chose to mess up on the regular old knitting parts that needed an increase 2-4 times per row. Really? The best part is after ripping back I just could not seem to get my count right to fix it. So why do we do this? And I'm not talking about beginners, that is expected. I'm talking about those of use who have been knitting for years. When I'm cruising thru Instagram I see endless posts of us all sharing our frogging misery. It's not just me. And not just little mistakes, sometimes we are ripping back inches of work or even worse, all the way to the beginning. I looked at the pattern yet again and said to myself, well why the hell didn't I just check my count when the designer put what the stitch count should be? I included a picture of this point in the pattern. The yellow highlight is where I should have stopped and counted my stitches but instead I plowed thru and was on the row AFTER the orange highlighted section and guess what, the lace pattern wasn't working out because my stitch count was off. Aarrgh. And I of course messed up way back at row 11. My round about way of getting to the point is that for me I seem to make my mistakes mainly for two reasons, I'm not paying enough attention and I'm too busy plowing thru to stop and take the time to read and make sure I'm where I should be. I'm guessing that for most of you, it may be similar reasons? It seems so silly right? I'm knitting to relax and de-stress yet for some reason I don't seem to be able to relax enough to enjoy the whole process. To pay attention to the pattern and to appreciate all that the designer has done to try to help me avoid these mistakes. So moving forward I am going to make a concerted effort to really slow down and pay attention to the whole practice of knitting (or making of any sort). Read the pattern before I start. Pay close attention to key spots where the designer is telling me to watch what I'm doing, and count more! It's ok to slow down, this is for fun afterall. A 2021 goal or new years resolution of sorts. Reality, I could probably take this approach on just about everything in life right! I would love to hear if you are prone to making similar types of mistakes and why you think you are making them? Or maybe your mistakes are totally different? Either way please share! Thank you for reading and sharing and don't forget to count when you are told! I hope you are having a wonderful and healthy holiday season!!!  All blended up and ready heading into the carder All blended up and ready heading into the carder Can you believe its December?! The main reason I can is because I just finished shipping the last of our inaugural subscription yarn club! I feel like I've been thinking about the yarn club for months. Well really for years is how long I've wanted to start one. 2020 seemed the year for something new and so be it! I'm so proud of how the first yarn club turned out. This is a dear yarn because it is the first time I have mill spun our sheep's dyed in the wool. What is "dyed in the wool" you ask, well let me explain! This first yarn club is 100% Shetland straight off of our two white ewes, Sweet Pea and her daughter Cream Puff, and then blended with our two rams Bert & Ernie. After shearing I skirted the wool (removed all the vegetable matter, poop, and other unwanted stuff), took the wool to the mill for washing and then it was time to dye. So when I say "dyed in the wool" it is still in lock form and only has been washed. Then into the dye pots it goes! I started out just having fun with this and using up some of the older pre-mixed dyes I had in red and black. Then I kept going, dyeing up other colors that I thought would blend out well such as blues and purples. Again using dye I wanted to finish up so I could mix up fresh bottles in different colors. I slowly dyed up about 3 lbs of wool this way. Then I decided what if I just left the ram fleeces natural. One of them is mostly white and the other is a lovely blend of white and gray. So I took a little over 3 lbs of their washed fleeces and went for it. So what happened? It's stunning! I'll admit though as it was first going into the carder I was a little concerned about how the colors were going to blend. Sitting on the carder infeed belt, they didn't look very pretty together. I was pleasantly surprised when it came off the carder and got even more excited every step of the way. The colors blended into a lovely shade of berry and the natural gray lended itself to give almost a frosty look to the yarn. And then there are little pops of the original blues, reds and purples throughout the yarn. I think it has so much depth and is truely one of a kind. Really each skein is! There are a couple skeins of this yarn available up in our online shop if you are interested in grabbing one or two for yourself. Shop here! If you'd like to see videos on the making of this yarn, Episode 3 of the Being Ewethful podcast is up on YouTube now! Follow this link to watch the magic happen. Thank you all for reading, for watching, and for buying from our small mill. We appreciate you all! Have a wonderful holiday season and stay healthly!!!  I hope this Thanksgiving week finds you all well and healthy! This holiday season is definitely a bit different from the past isn't it? I'm finding myself, well first surprised that it is already here. In addition feeling a bit less frenetic. I won't be out doing a lot of in person shopping but will instead be hunting down small businesses I can buy from online. Meanwhile Mitch has been busy hanging Christmas lights which will certainly add some holiday spirit to the air. Oh and I'm so glad to see that there are endless cheesy Hallmark-esque movies I can watch on Netflix. My favorite for knitting and spinning! But back to last week. We headed on a quick day trip to Portland so that Mitch could work on some upkeep at our property up there. Meanwhile I made a trip just down the road (literally) to what was once the place that they used to do the wool washing for Pendleton. I love this place. This is my third or fourth visit and everytime I learn more about wool from Keith, Dan and Allen, the guys who run the facility. I have of course gone thru the building before with them, but this time I recorded and have shared some of the videos in Episode 2 of the Being Ewethful video podcast. If you'd like to see, please follow this link and check it out. I thought I would expand on the trip here on the blog... From the moment I drive in I get giddy with excitement. You drive around the back of this big building and there you see a sign painted on the outside "Columbia Wool" with an arrow leading you. The office is just up the stairs and I am always greeted with such a welcome from these guys. And of course, we talk wool! Getting a chance to talk with professionals with such long histories in this industry is an inspiration for me and I always try to take in everything they say. All three of them are able to class wool - classing is a way of sorting wool into different levels of fineness or microns - which is a skill all its own. They all worked here at Pendleton when the scouring mill was operational and have such stories. As we go on our tour I can't help but put all the pieces of equipment back in there place and imagine what it would have been like. The conveyers overhead moving wool to and fro. Employees all around running the machines. And the level of noise as all the machines were doing their jobs. It is such a big impressive building that it brings me joy to think of it fully operational. These days the facility is used for a couple purposes. One is that it is a place where local shepherds and shearers come to sell their raw wool. As Keith mentioned, most of the local wool that is dropped off is not enough quantity to fill one bale. So one of their jobs is to sort thru the wool, class it and re-bale it for cleaning. They are looking for white wool only so any other natural colored wool is immediately pulled. The reason for white wool is that it dyes up easily and uniformly. After being skirted thru, the re-baled wool is shipped to Texas for scouring (washing). This used to be the main job of this facility. Years ago the scouring ceased happening here. The main reason being that water is expensive (I can attest to that given the business I used to own down the street!). Both the amount used and the output. And of course all that is put back out in the water is closely monitored and charged accordingly. The wool soaps, the lanolin, the debris are all taken into account. The long and short of it is that the cost to clean the wool at the facility became more than the cost to ship all the wool by trucks to a scouring facility in Texas. So that is how it is done now. Actually most of the wool scouring in our country is done in Texas. After it is clean the wool is shipped back to the facility in Portland and/or the two mills in Washougal, WA or Pendleton, OR. In addition to overseeing the movement raw wool to and fro, this site in Portland is also where most of the wool from around the world is shipped to. The main countries that they receive their wool from are Australia, New Zealand and South America. The main reasons they are importing wool is that it is hard for them to get enough of the wool they are looking for in the US. They need very low vegetable matter as well as branding paint-free white wool (a paint is often sprayed on the backs of sheep to denote whom the sheep belong too). Apparently the wool out of Australia has only 0.1% vegetable matter. Now that is low! The reason it is so low is that they are mainly out on large pastures with shorter grass which keeps vegetable matter and mud to a minimum. As you walk the building you are surrounded by massive bales of wool. Each bale is stamped with the grade of wool inside and it all will be used for different Pendleton products. The finer end (lower micron count and softer) is generally used for their mens shirts and other next to skin apparel. The courser wools go towards items such as blankets. As for what I bought. I got one beautiful fine wool fleece that I hope to crack into this weekend for a bit more skirting. I'm not sure what I will do with this fleece? Play most likely! I also bought another secret batch of wool which I'll let you in on in a few weeks. So there you have it. A little more about my trip. They do accept visitors but during the pandemic and out of respect I would advise that you call ahead first. Also you must WEAR A MASK!!! As always thank you for reading. And now for watching too! Please be safe this holiday week. Do a lot of making and when you are out and about please wear a mask! Until next week, craft on!  A moment from the first episode! A moment from the first episode! Hey everyone! I didn't forget you over here on the blog. I took last week off so that I could get the first Being Ewethful video podcast up on YouTube. If you haven't had a chance to watch it yet, please pop over to the Ewethful Fiber Farm & Mill channel or follow the link whenever you have time. In the first episode I talk a bit about my journey to owning the Mill. As well as a bit about the Jacob sheep breed and wool as well as some knitting and spinning of course. And finally take you on a quick tour of the Mill. My reason for doing the podcast is two-fold. One reason is to allow people regular access to what it is like to own a mill, how the process happens and of course lots of videos showing how it all works. Another reason is to get a chance to reach out and show to you all some our yarns and fibers, introduce new products and show you how I use them in my crafts. And finally I get to talk about wool! How I source it, how it behaves for processing and how using locally sourced fibers is a sustainable and natural option. So I guess there are a lot of reasons! Oh yeah, and I miss you all and thought this was one way to reach out and connect. I plan to put out a podcast every two weeks (the next one will be released Tuesday November 24th) so if you like the first one, please don't forget to "like" it, subscribe to our channel so you know when new ones are released, and please comment with questions or things you'd like to see. And thank you for all the different ways you support me, the mill, and our farm family. It has been a bit since I did a farm update so I thought I would let you know what has been going on lately. First and foremost harvest and planting are over the year. Wahoo!!! On the grass seed farm the guys are mainly working on winter projects - fixing things that broke during the summer, clean-up, hauling seed in for cleaning and fabricating new items they hope to have for next year. Mitch gets to be around our place more which doesn't mean that he is sitting around. I'm actually not sure that he knows what that is? Any moment there is daylight, wait no, he'll work outside in the dark. Ok any moment it is dry out, wait no, he'll work in the pouring down rain. Ok how about any moment until I call him in for dinner (which is late in our house) he is out working on the property. There is always more to do, or repairs to make. We have one last pasture space that has yet to be fenced so that is the big outside goal. Then we will have 5 total pastures and since we generally run the animals in 3 pastures at a time, this will allow for some field rotation which in turn allows the empty pastures time to rest and regenerate. Last week I sent my last foster for the year back to the Humane Society. She was actually an adult cat that had an owner which is why I didn't post any pictures. She was a McKenzie fire cat so while she has parents, they no longer have a home. Many volunteers are helping to house these cats (and dogs) while people get their bearings. If you have an urge to donate Greenhill Humane Society is always taking donations of food, money, and animal items to help shelter and disaster recovery animals. I was so sad to see her go, but somehow one thing settles around here and the next takes its place. Within a few days of dropping off the foster, June the pony started having foot issues. She is not the most spritely horse given her old age and previous neglect, but this week she stopped letting me pick (clean) her hooves which is abnormal for her. I finally realized that the foot she was letting me get to was the one actually hurting her. She was holding it up for me because she didn't want to bear weight on it. Ooof, not good when you are the size she is. So out came the vet who diagnosed her with a very bad infection inside her hoof caused by who knows what. A massive round of antibiotics later and she is on the mends. It was a very rough couple days as her response to the meds was slow. She still has a mild limp but is getting much better and moving about the pasture again. We'll be keeping a close eye on her and hoping we don't need more medications. Hoping for the obvious reasons but also because she was SOOO stubborn about taking those meds. I can tell you we went thru a lot of applesauce! We've also recently had a visit from the "alpaca doctor." Time for bi-annual check-ups, deworming and toe nail trimmings. They all behaved so well until our last girl Khaleesi. If they all behaved, what fun would it be right? All are in great health and definitely not underfed! Meanwhile we moved the ewes that we are breeding back into their old pasture with the other ewes and wethers (castrated males). I think they are relieved to get away from the boys! The rams meanwhile seem quite happy to be back together. They are brothers and have always been together except for the month here and there for breeding. They love their time with the girls but after awhile they start head butting the fence between themselves in hopes of knocking it down. Oh Brothers! While moving sheep around we started back into trimming hooves and deworming them all. Mitch and I both have backs that do not love the postures necessary to do this so we tend to break it up doing 4 or so each week. Slow going but we get it done and don't break ourselves in the process. Plus it keeps us in check so I don't go too breeding crazy with the ewes! The last big thing around the home farm is that we have started letting the big dogs, ElsieMae and Cash, into the house when we are home. They used to be limited to the den and of course endless outdoor space but in an effort to keep the inside space less muddy we are keeping them in more during the winter which means they need a bit more people time. Or so my guilt thinks anyway. They are loving it! Really they are mostly loving the cats and the opportunity to try to catch falling food while I cook. They are doing amazingly well and on nice days still enjoy being outside keeping an eye on out for predatory birds and chasing squirrels. So that is the latest on the farm update. The winter rain is here which means its time to tuck in and knit right?!!!! Do any of you have winter projects to keep yourself busy during this very weird year? Thank you for reading. And maybe even watching! Take care, stay healthy and craft on!!! |

AuthorI am Kim Biegler, the owner and operator of Ewethful Fiber Farm & Mill. I create hand spinning fibers from locally sourced wool and teach others online how to hand spin their own yarn. Archives

August 2023

Categories |

RSS Feed

RSS Feed